Technology

Controlled behavior through distributed break up

The high stiffness and ultralight weight of the engineered Thin-ply Carbon Diaphragms (TPCDs) enable a wide range of pistonic motion, while the concept of distributed break up ensures a controlled break up behavior with low distortion.

By varying the properties of the TPCD in different areas and directions, the symmetric break up modes are eliminated and replaced with smaller and local distributed break up modes, enabling a more linear frequency response.

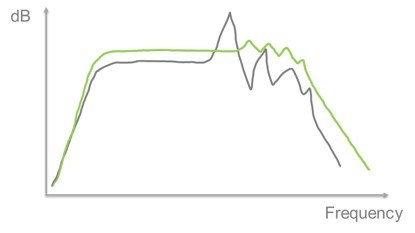

The big peaks and dips of the conventional diaphragm in gray are replaced by smaller ripples in the Composite Sound TPCD as shown in the green curve.

Schematic frequency response curves titanium (gray) vs. Composite Sound Thin-ply Carbon diaphragm (green).

Second Generation TPCD

– Composite Sound MetamodalTM

Composite Sound Metamodal technology builds on Thin-ply Carbon Diaphragm technology with distributed breakup modes and takes it to a whole new level, enabling cones and diaphragms with engineered modal behavior.

The term “Meta” (as a prefix for beyond / transcending) describes something that goes beyond the naturally occurring. A “metamaterial” is designed, or artificially structured, to have properties or determined behaviors that are not occurring in its natural state.

Composite Sound Metamodal cones and diaphragms are engineered for a performance level and specific behavior that is beyond the material properties that bounds the performance of traditional speaker diaphragms. In the same way that metamaterials can be artificially structured to control light, and metasurfaces to manipulate soundwaves, Composite Sound Metamodal technology controls and manipulates resonances.

Engineered modal behavior

By optimizing the thickness and stiffness in all areas, the Composite Sound Metamodal diaphragm can be engineered for a tailored modal behavior — frequency response linearity, improved pistonic motion, moving mass optimization — as needed.

In a traditional speaker cone as exemplified with an aluminum cone (below), the modal behavior for a given geometry is set and can’t be changed in the cone itself.

In a Composite Sound Metamodal cone with a given geometry, the modal behavior can be tailored by optimizing thickness and stiffness in different parts of the cone or diaphragm.

This is shown as three variants – Composite Sound Metamodal A, B and C respectively – all of the same cone geometry, thickness and mass.

Traditional speaker cone with an aluminum cone

Composite Sound Metamodal A

Composite Sound Metamodal B

Composite Sound Metamodal C

Tailored frequency response

The ability to engineer the modal behavior, in other words to tailor how different parts of the cone or diaphragm behave at different frequencies, enables the ability to tailor linearity, distortion, directivity etc. This is exemplified with this set of frequency curves showing different Composite Sound Metamodal cones of the same geometry in the same driver, engineered with different modal behaviors with resulting different frequency curves.

TeXtreme® thin-ply carbon material technology

The unique checkerboard pattern of a Composite Sound Thin-ply Carbon Diaphragm is the result of the material science and technology used to engineer them: TeXtreme® thin-ply carbon fabrics.

Where a conventional carbon fabric is woven from thick round yarns, a TeXtreme® carbon fabric is woven from ultrathin carbon tapes.

This results in:

- Higher stiffness

- Lower weight

- Tailored properties

All adding up to freedom of engineering and design.

Engineered cones and diaphragms, unique aesthetics

We use composite and acoustic simulations to optimize thickness, stiffness and damping at every given point of the cone or diaphragm, thereby engineering a solution with tailored modal behavior, maximum stiffness, and ultralight weight.

It also makes the cone or diaphragm look like nothing else. It is the engineering and material science that creates that unique Composite Sound aesthetics.